Hygienically packed:

Packaging machine for brackets successfully put into operation

Released: 05.03.2019

A global innovation was inaugurated recently by Dentaurum: the first robot-controlled packaging machine for dental brackets. CEO Mark S. Pace and his wife Petra symbolically cut the ribbon which hailed the start of the automated, hygienic packaging of brackets.

Mark S. Pace already had the idea of packaging brackets automatically and hygienically some years ago. He says, "The hygiene of our products has always been extremely important to us". The development of new production technologies made it possible for this idea to be implemented successfully in his own company. The packaging machine must be in a position to grip the brackets fully automatically, lay them in the right position in the pockets, seal the packaging with two layers of foil, and place it in an outer packaging.

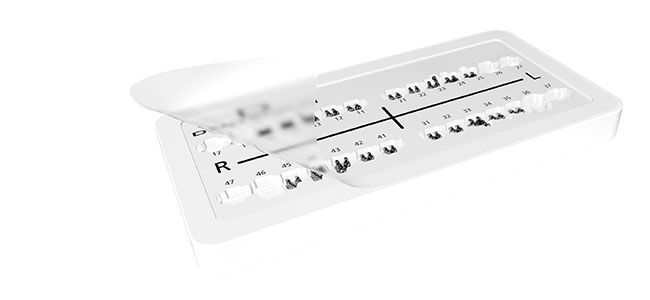

Dentaurum is the first dental orthodontic company worldwide to package its brackets itself in blister packaging. At first, the discovery® smart brackets will be machine-packed in the new, white acrylic blisters with a one-case assortment per blister. Two seals on the packaging guarantee the brackets are genuine.

A solution beneficial to every orthodontic office

The blister packaging is pleasing to the eye with a white, lightweight insert with rounded corners and edges. The brackets are placed by robots with the base facing downwards and in the order of the FDI notation into the pockets of the packaging which are designed to suit the discovery® smart series. The blister packaging is sealed with two transparent foils, the lower of which is perforated for the removal of the bracket. The double foil therefore offers optimal protection against contamination. The orthodontist receives hygienically clean brackets which he can remove with the aid of tweezers and place directly into the patient's mouth with no need for additional cleaning. That saves time.

Hygiene and cleaning process

The brackets undergo the same automated cleaning procedure as always before they are packaged. In the course of converting from manual to automated packaging, Dentaurum optimized the chain of hygiene. In addition, the instructions for use state that the brackets should not be touched by hand, nor should they be contaminated in any other way.

Following production, the brackets undergo an extensive cleaning process consisting of up to seven computer-controlled cleaning steps. They are packed using the fully-automated packaging process, then sealed and labeled.

We aim in the next few years to offer worldwide all of the Dentaurum brackets in this new, hygienic packaging. Dentaurum will ring in the age of machine packaging with the premium metal brackets discovery® smart whose small, modern design unites with the brilliant properties of the discovery® bracket family.

discovery® bracket family

The bracket is based on the successful design of the discovery® bracket family: large, rounded tie wing undercuts with room for all types of ligatures, even for multiple ligatures or combinations with elastic ligatures. The base of the brackets has been optimally adapted to the tooth contour using CAD (Computer Aided Design). This facilitates positioning the bracket on the tooth. Since all brackets within the discovery® family have the same low In-Out of only 0.7 mm, they can be combined with one another with no need for compensation bends.

More information:

DENTAURUM

GmbH & Co. KG

Turnstr. 31, 75228 Ispringen

Tel. +49 7231 / 803-0

Fax: +49 7231 / 803-295

E-Mail: info@dentaurum.de